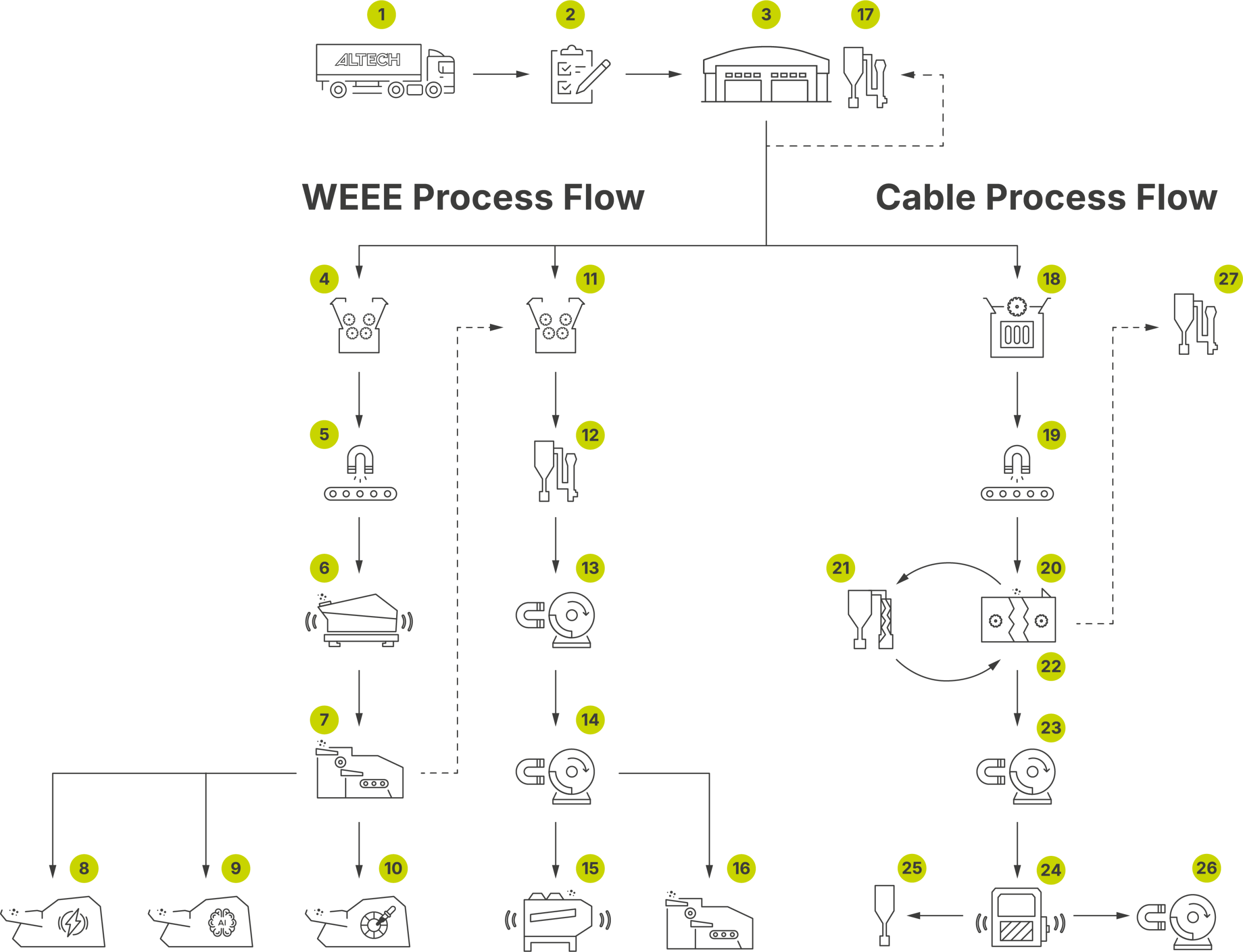

At our facility in Southend, we segregate and then process a variety of WEEE and metal-bearing products.

Specialising in complex electronic waste streams — from small consumer devices to large-scale critical infrastructure — Altech has developed advanced systems to recover the valuable resources embedded in WEEE. Our processing lines incorporate cutting-edge technology, including near-infrared (NIR) and AI-powered optical sorting in order to recycle previous generations of technology.

From these materials, we produce high-quality recycled commodities ready to be shipped to end users across the UK and Europe.

Typical materials produced:

Aluminium

Cast, Shredded, Granulated

Copper and Copper Concentrates

Shredded, Granulated

Brass, Zinc and Lead

and other Non-ferrous Metals

Ferrous Metals

Iron, Steel, Stainless Steel, Nickel Alloys

Circuit Boards

Containing Gold, Silver, Palladium, Platinum, Copper

Mixed Shredded Plastics

ABS, PC, POPs Fraction

Speciality Metals

Tungsten, Titanium, Tin/Lead, Silver-plated Metals)

Intelligent sorting

Upon arrival, all materials are assessed and categorised according to their physical composition (e.g. ferrous, non-ferrous, or plastic-based), material value (e.g. high-grade PCBs vs. low-grade), and hazardous characteristics, including the presence of persistent organic pollutants (POPs).

Targeted removal of hazardous components

Equipment containing hazardous elements—such as batteries, LCD screens, or capacitors with PCBs—is screened and subject to careful manual dismantling. Hazardous components are isolated for compliant disposal or treatment, while the remaining assemblies are redirected through our automated processing systems.

Automated shredding and precision separation

The majority of WEEE is processed through Altech’s automated shredding and separation systems. Material is reduced to a homogeneous particle size (typically <30mm, often as small as 15mm) and sorted into clean fractions using an advanced array of equipment including the latest in AI-powered optical sorting.

Clean, high-value output streams

Altech’s process achieves near-total material separation, generating high-purity outputs including:

- Aluminium and aluminium alloys

- Copper granules and concentrates

- Steel and stainless steel ferrous fractions

- Zinc and brass concentrates

- Mixed plastic polymers containing POPs

- Printed circuit boards (PCBs) in various grades